Why Luxor?

Our coaters

MADE FOR SEM

Successful industrial and academic SEM labs, where image quality and high-resolution imaging are of paramount importance, consistently choose LUXOR sputter coaters.

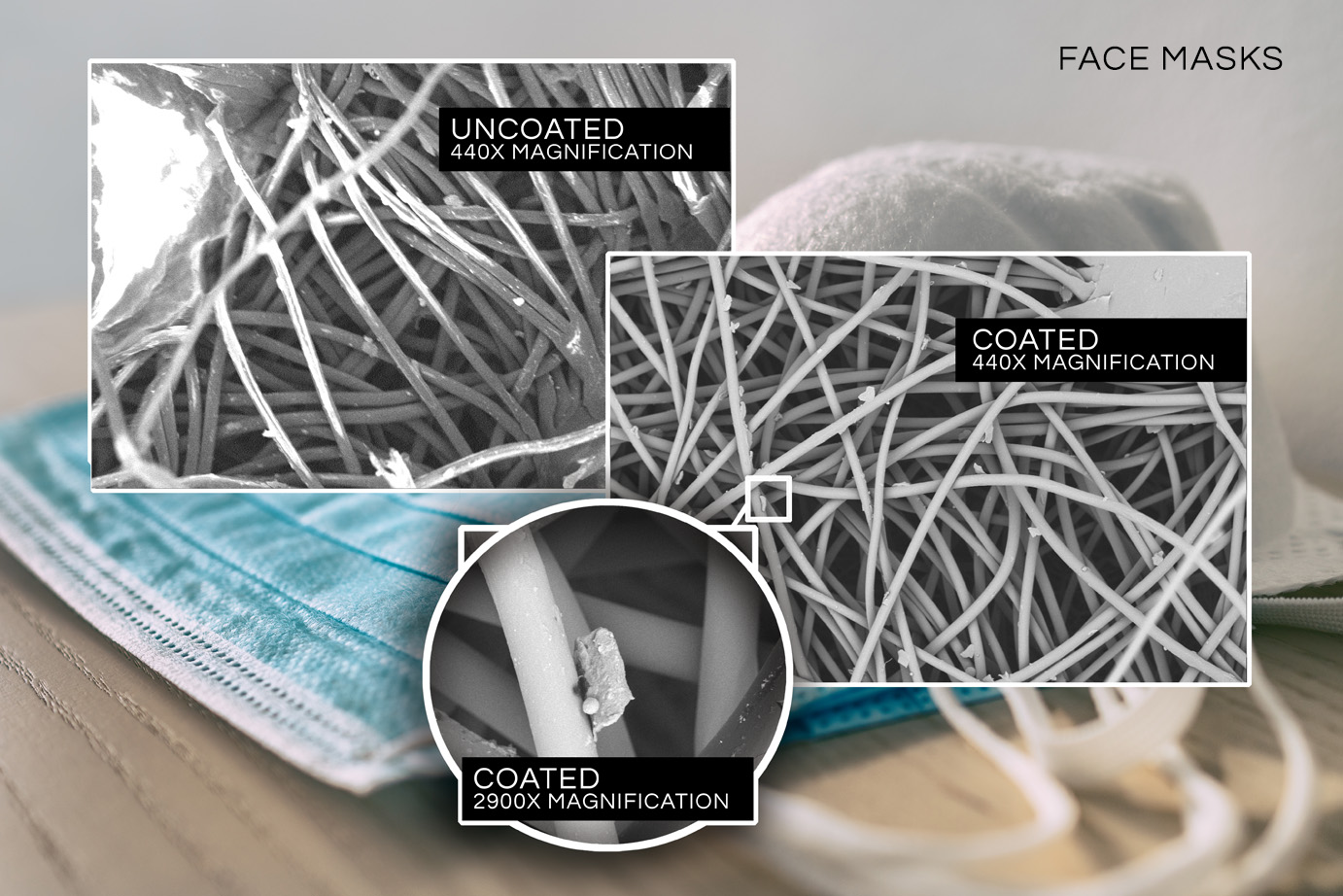

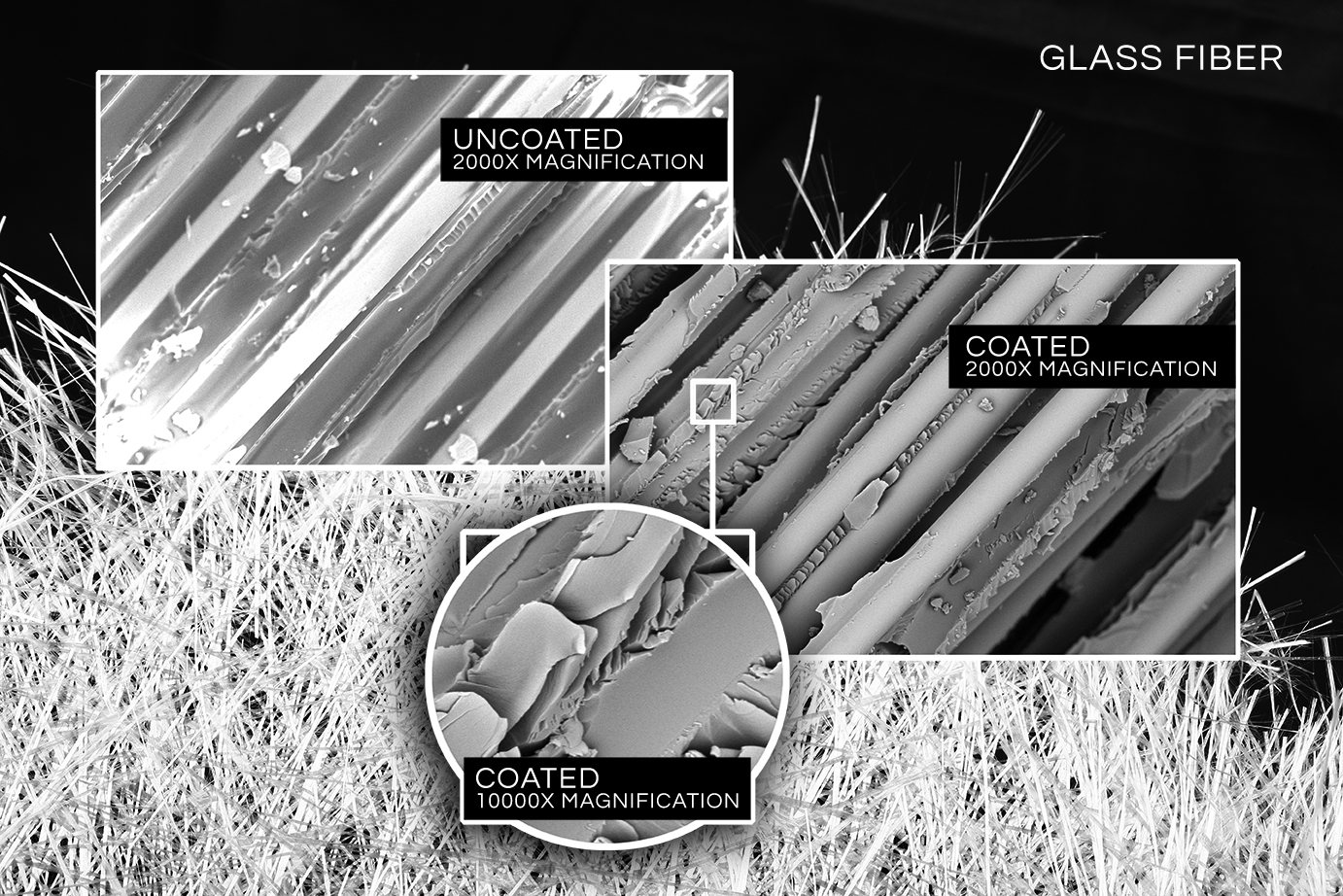

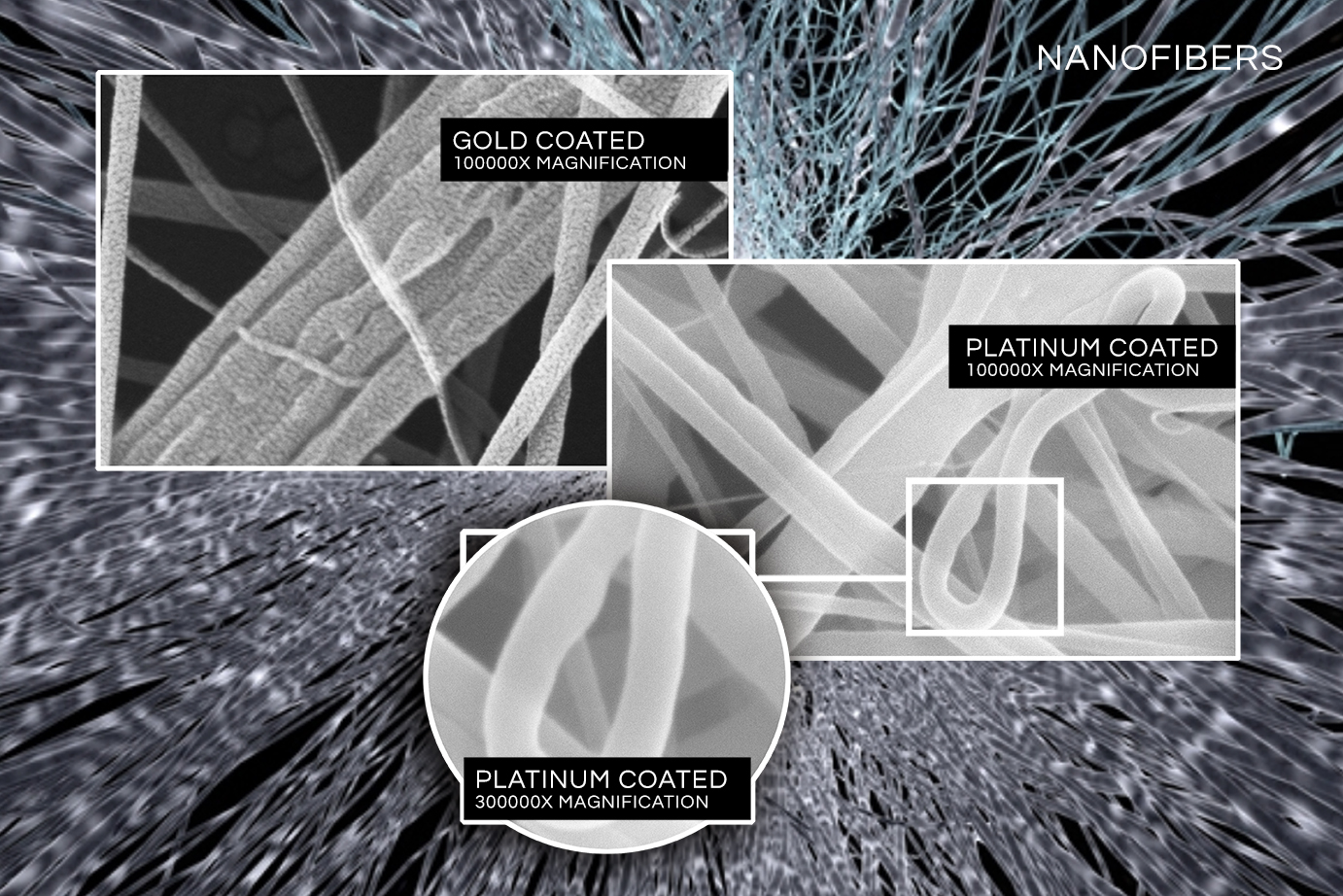

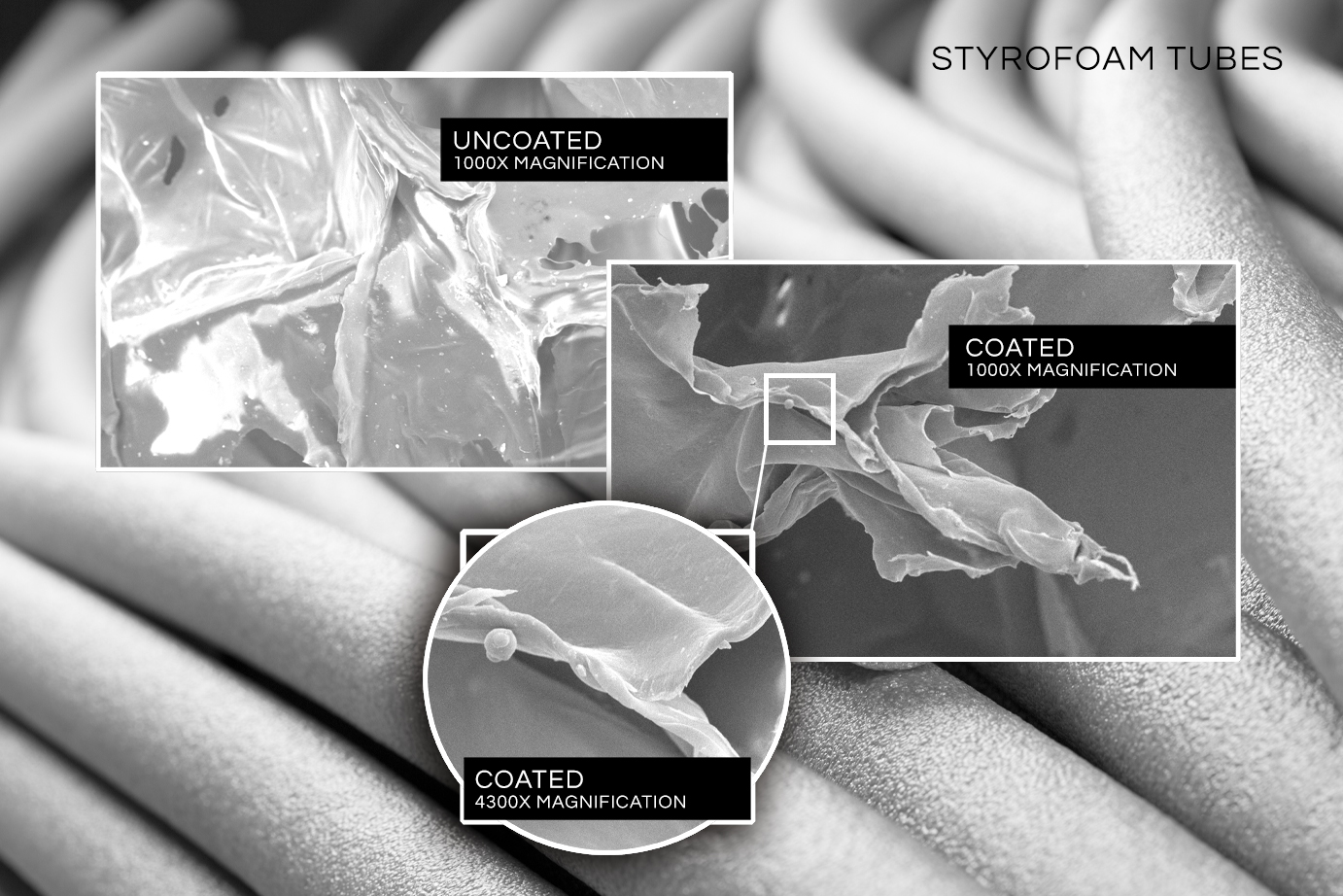

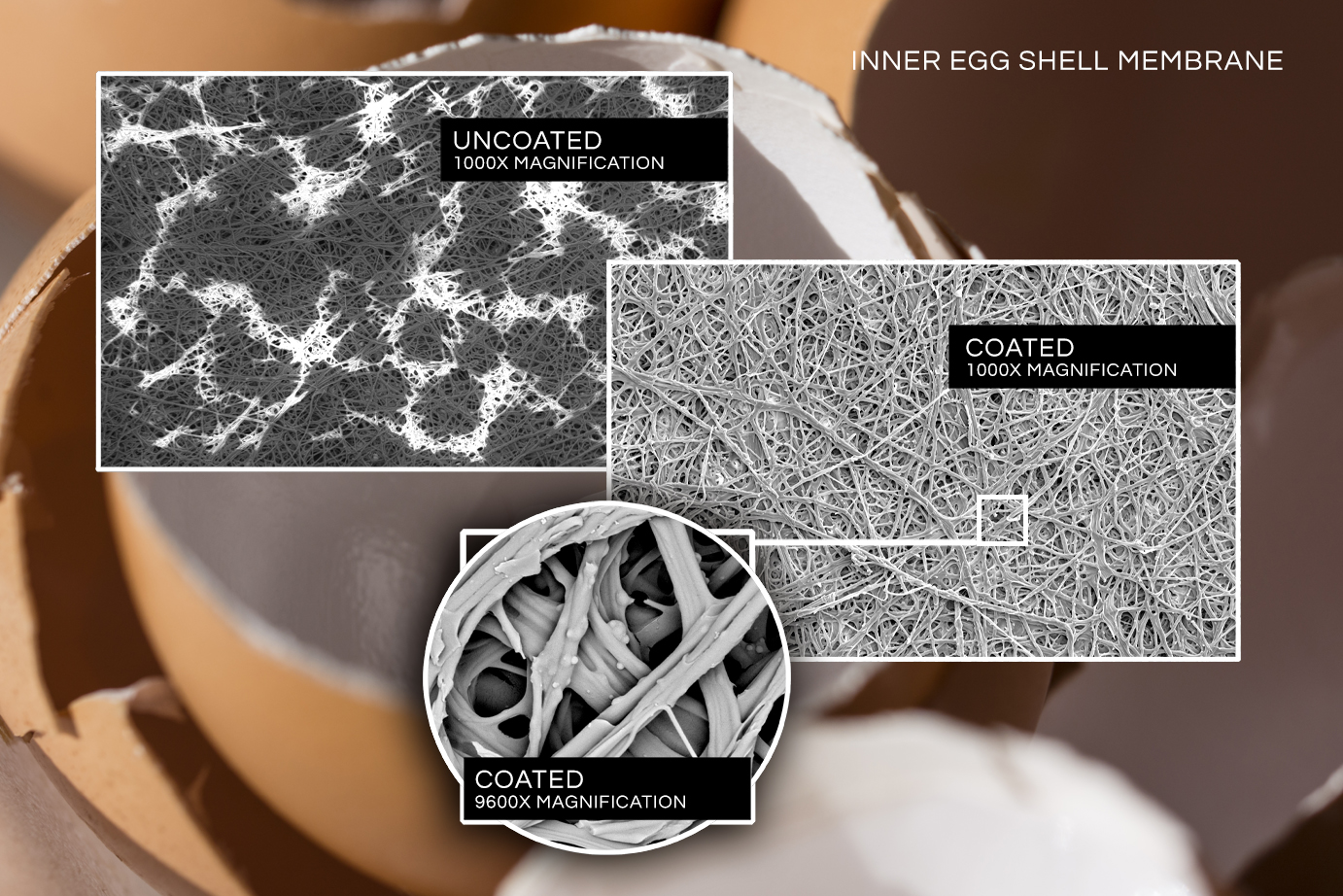

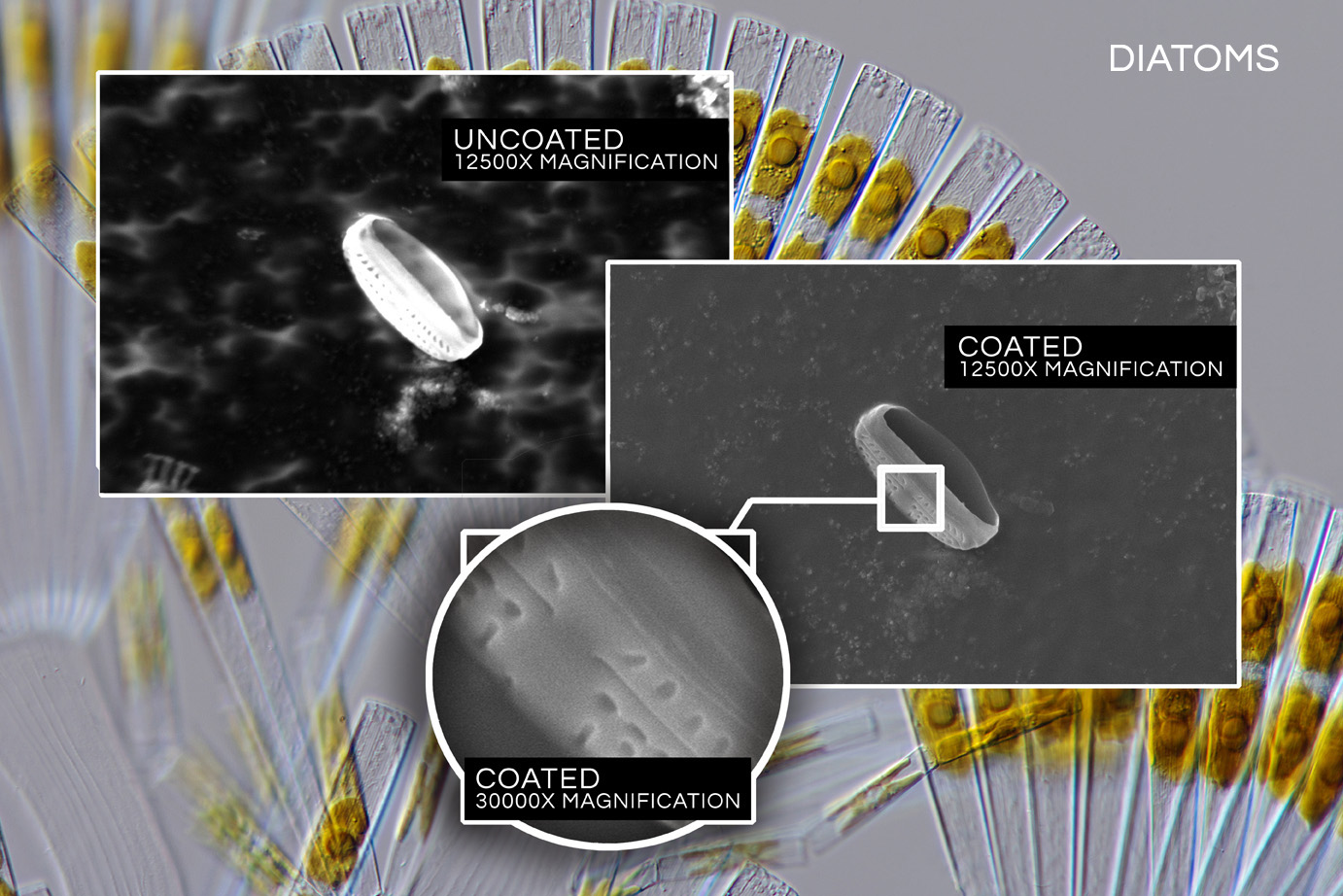

Prevent sample charging, enhance edge resolution and provide a better protection of electron beam sensitive samples. This is exactly what LUXOR sputter coaters, made for SEM, are doing.

INNOVATIVE TECHNOLOGY

At LUXOR, we believe that the best and most reliable sputter coating for SEM imaging can be done differently. With smart technology and innovative design. Innovation and smart design should be accessible for every user. That is why we have built a series of highly advanced, fully automated sputter coaters for SEM sample preparation. Our mission is to make SEM coating smart and easy. For every user.