Markets

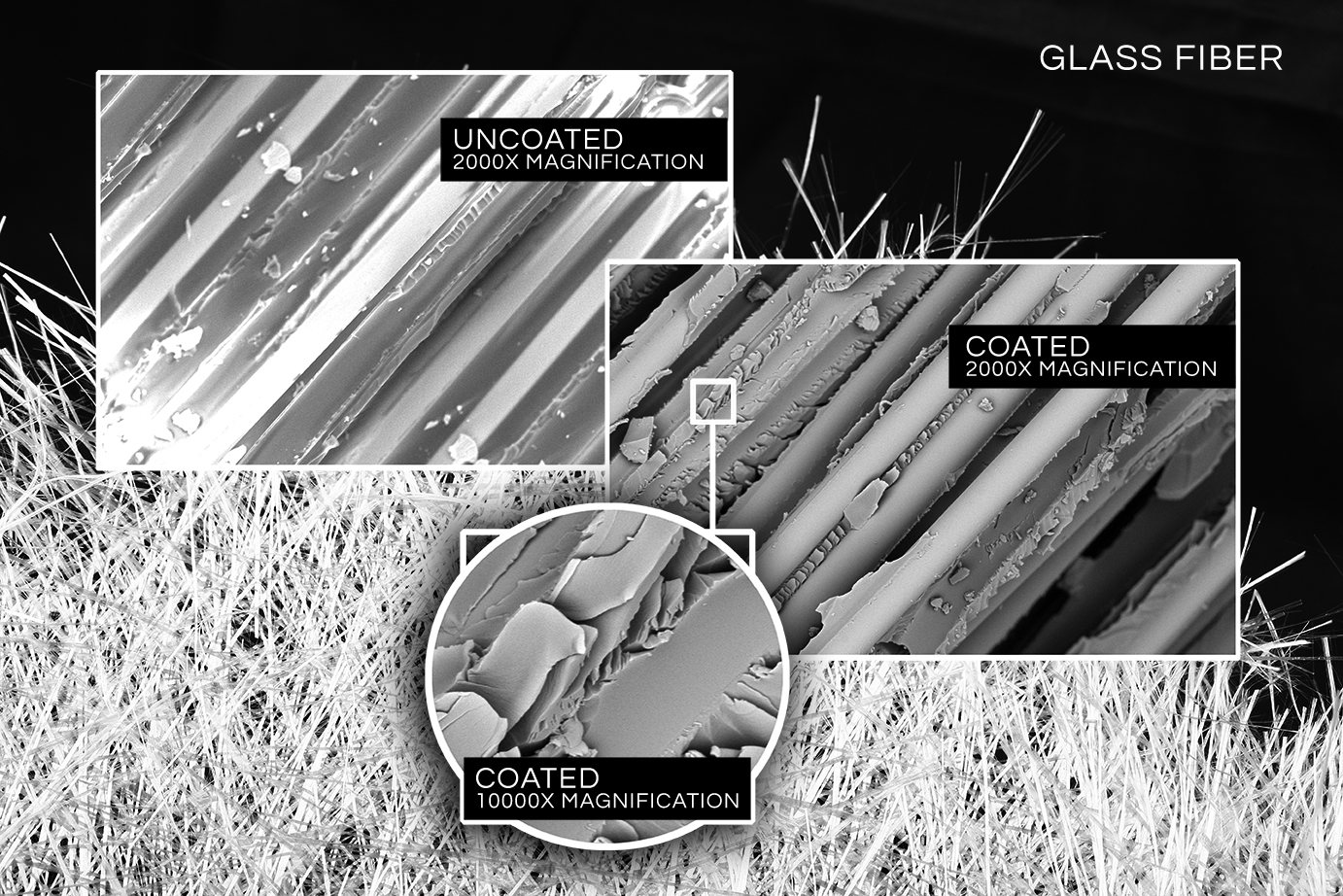

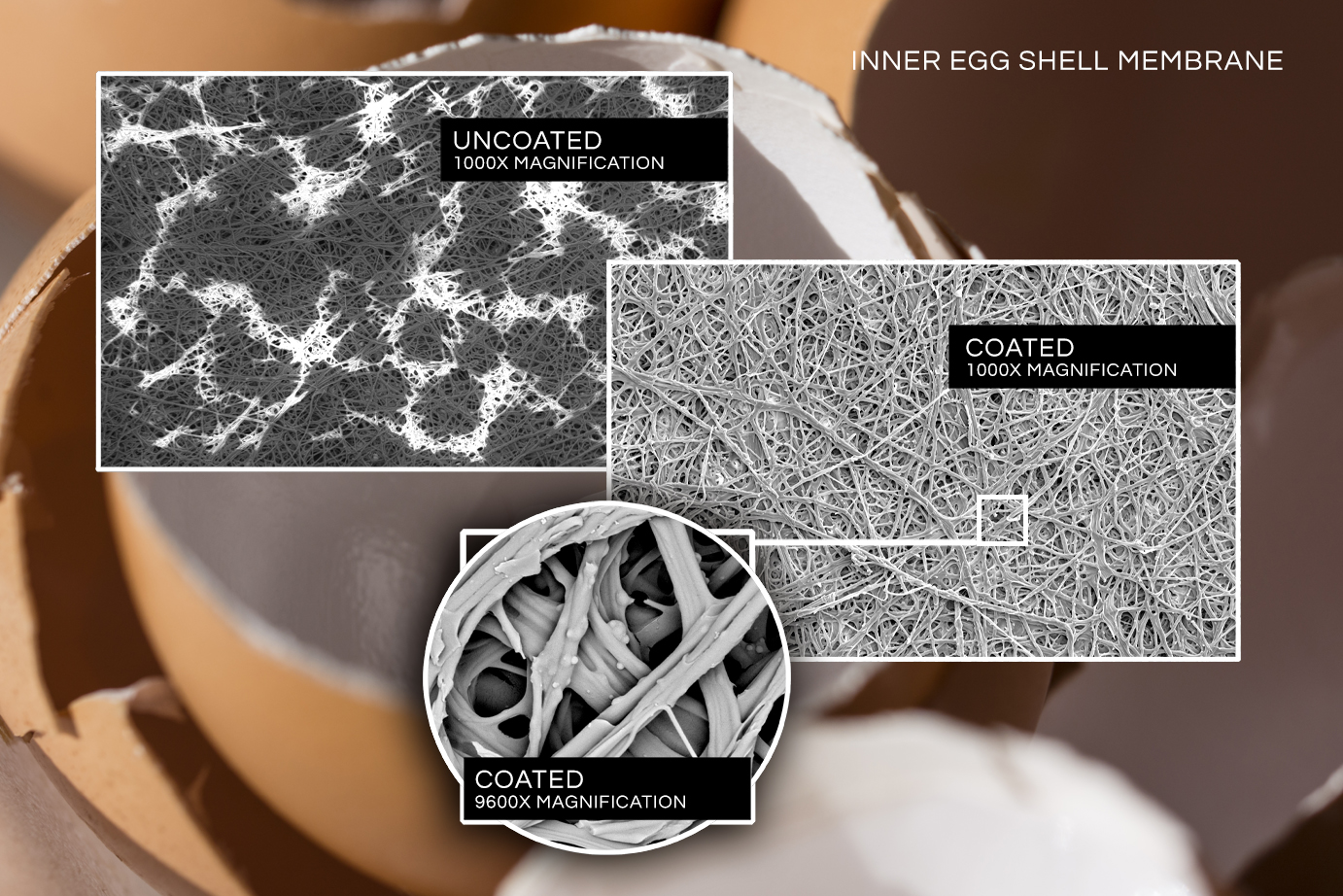

LUXOR’s highly advanced metal coaters (Au/Pt) are extensively used for many applications within the field of materials science – such as pharma, life science, electronics, polymers, ceramics, as well as for academic purposes.

Materials science

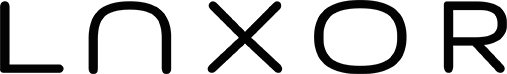

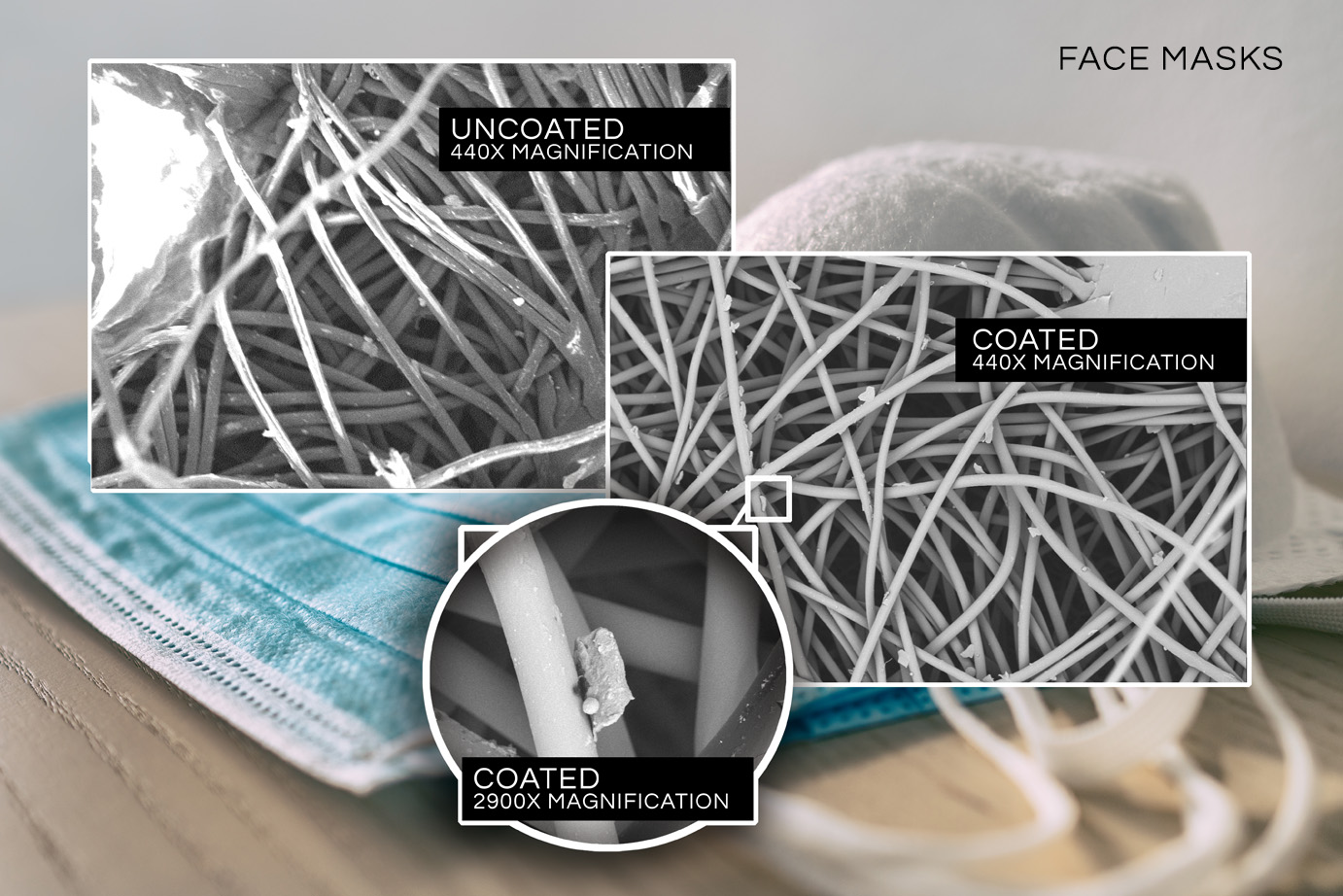

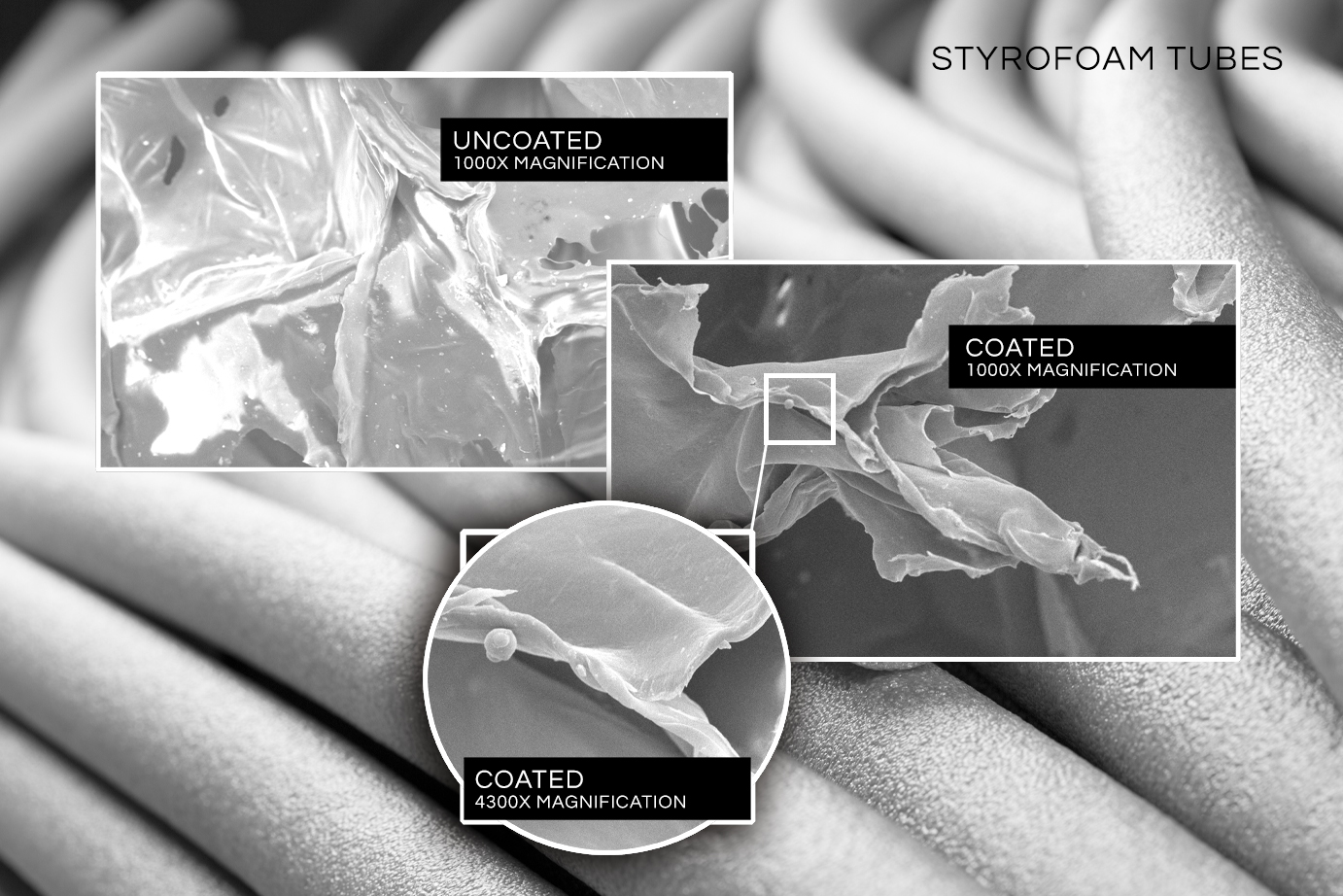

Materials science comprises many different branches and covers a wide range of materials like polymers, filters, metals, pharma, textiles, coatings, ceramics, life science applications, electronics, and so on.

The LUXORAu and LUXORPt metal coaters are widely used for all of these applications, particularly for electron microscopy (SEM and FEG-SEM) purposes where sample charging might be an issue and when working with beam sensitive materials.

The list of materials science applications ranges from particle characterization, analysis of the micromechanics of composites, visualizing the morphology of plastics, root cause analysis of different materials etc.

Todays’ materials science labs have become a central hub for product development, solving customer issues and high level quality control applications. Despite a wide diversity of incoming materials and their related issues, reproducible and user friendly testing methods have to be readily available and accessible to operators who only have a limited knowledge of the equipment. Moreover speedy and high throughput solutions are crucial to cope with the everyday work.

This is why the LUXOR fully automated metal coater fits perfectly in your lab.

In the LUXOR knowledge center you will find application notes and technical guides that are of interest for a wide range of industrial and academic environments

Academic applications

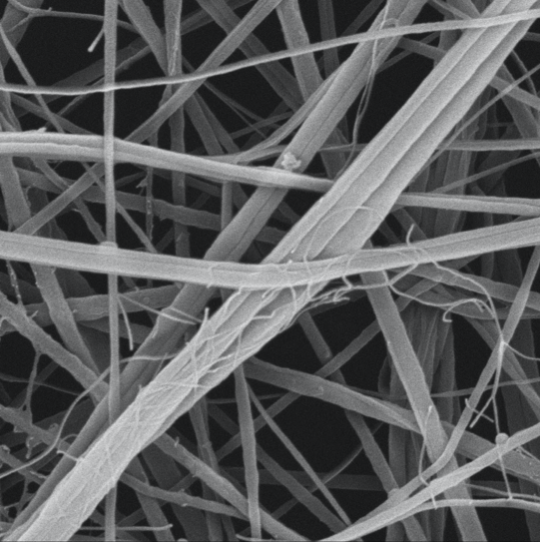

Working properly with a SEM or FEG-SEM microscope demands – amongst other things – for extensive knowledge about sample preparation.

To this end, the leading scientists of tomorrow learn how to work with LUXOR coaters in universities all over the world.

The LUXORAu and LUXORPt metal coaters can cope with a wide diversity of sample materials and are therefore particularly suitable for academic applications.

In a university setting, many different operators, ranging from students to senior researchers are using SEM technology and related sample preparation techniques such as sputter coating on a daily basis. There is also the wide diversity of specimens and materials for which a reliable sample preparation technique is essential.

Thanks to the fully automated operation and the optimised user interface of the LUXOR coater, the chance of human errors is minimal.

In the LUXOR knowledge center you will find application notes and technical guides that are of interest for a wide range of industrial and academic environments