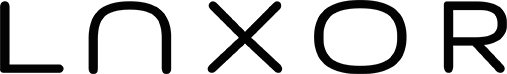

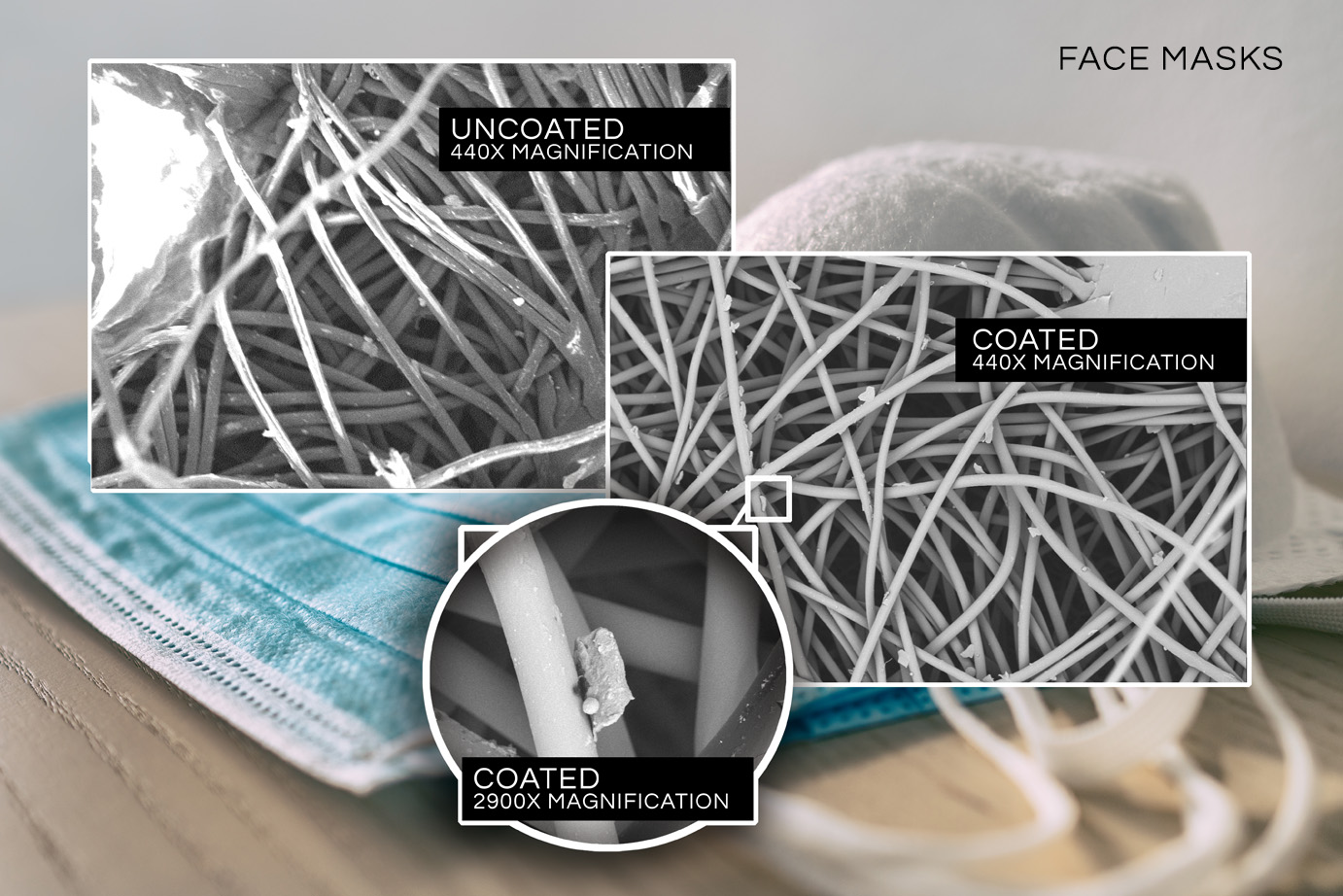

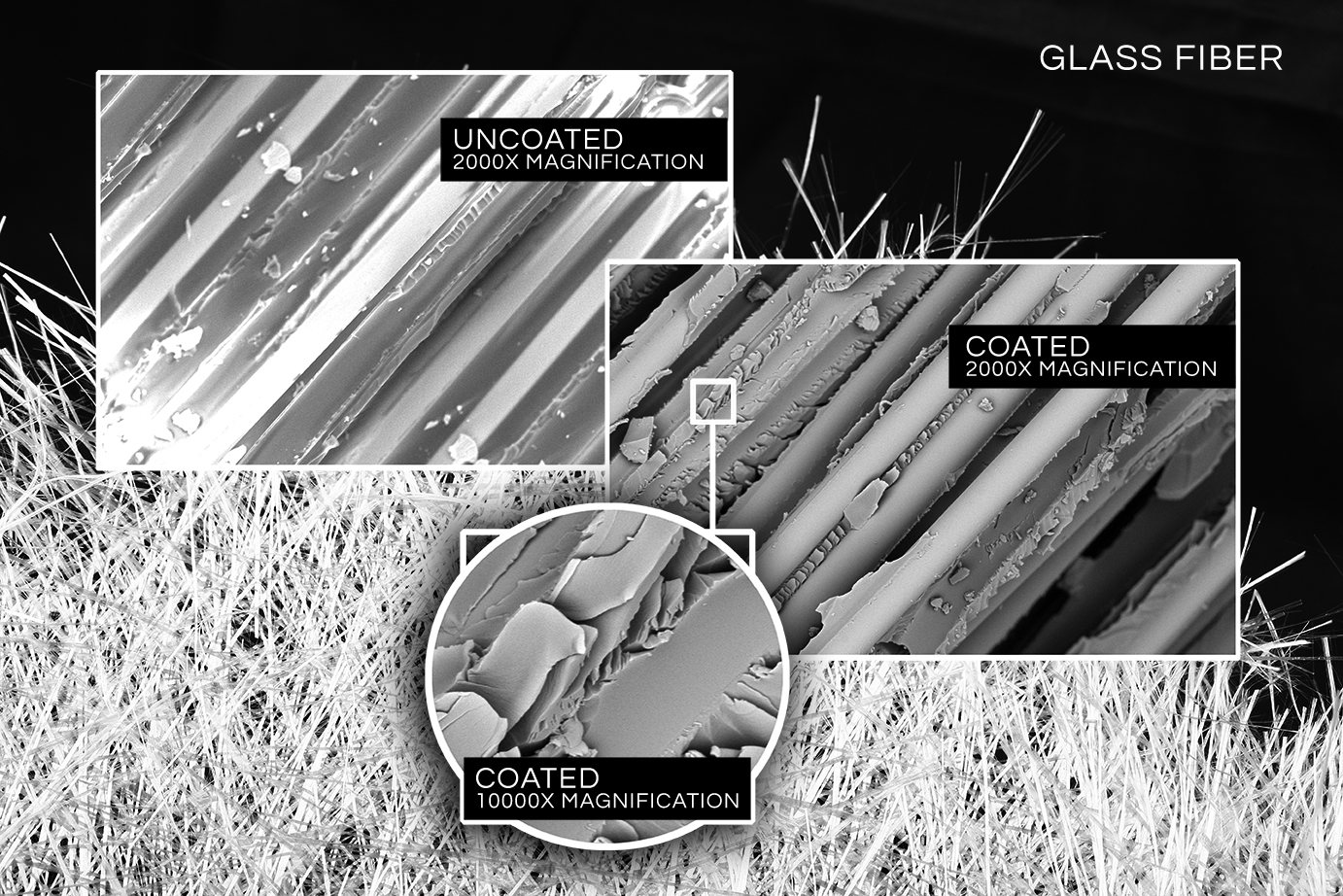

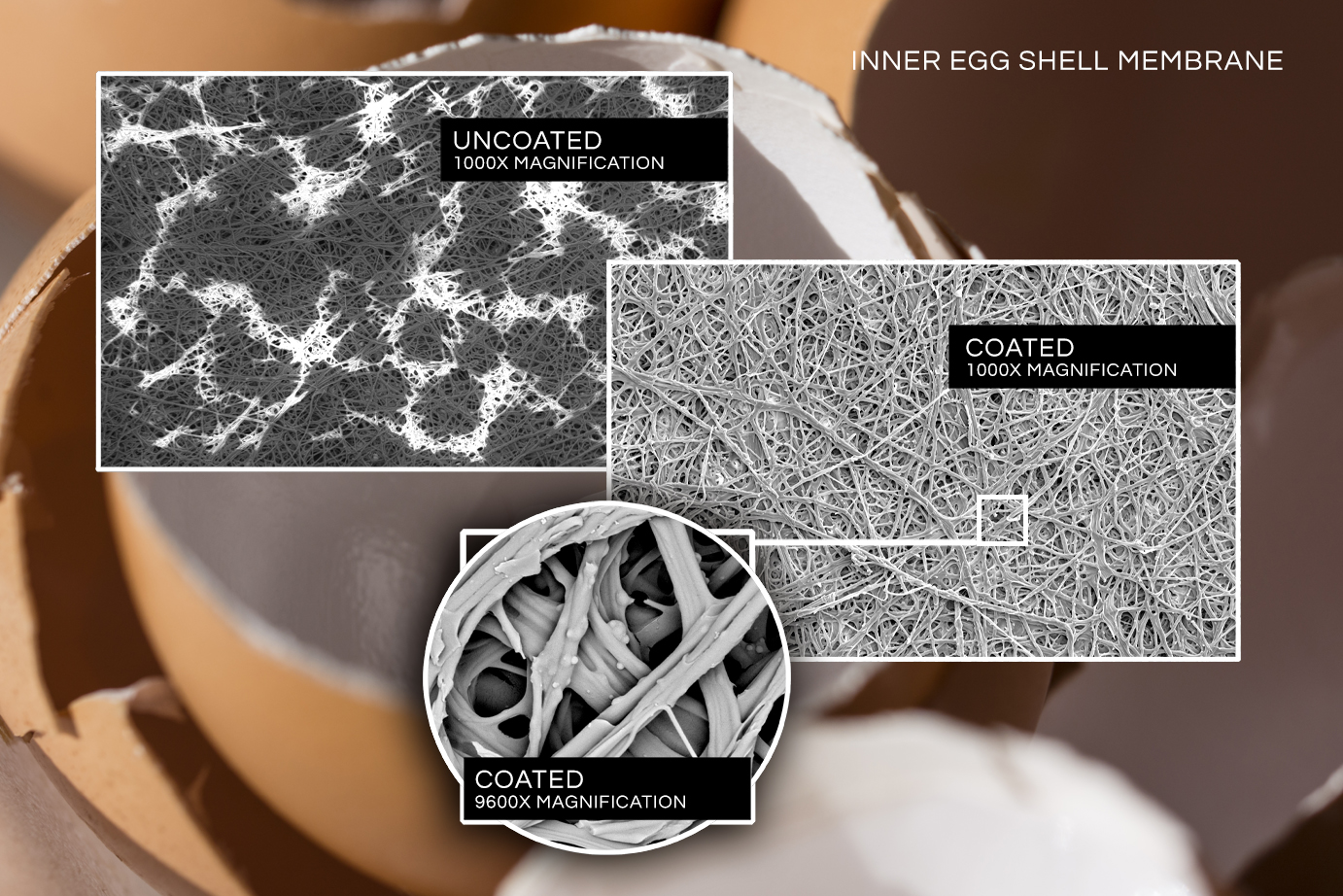

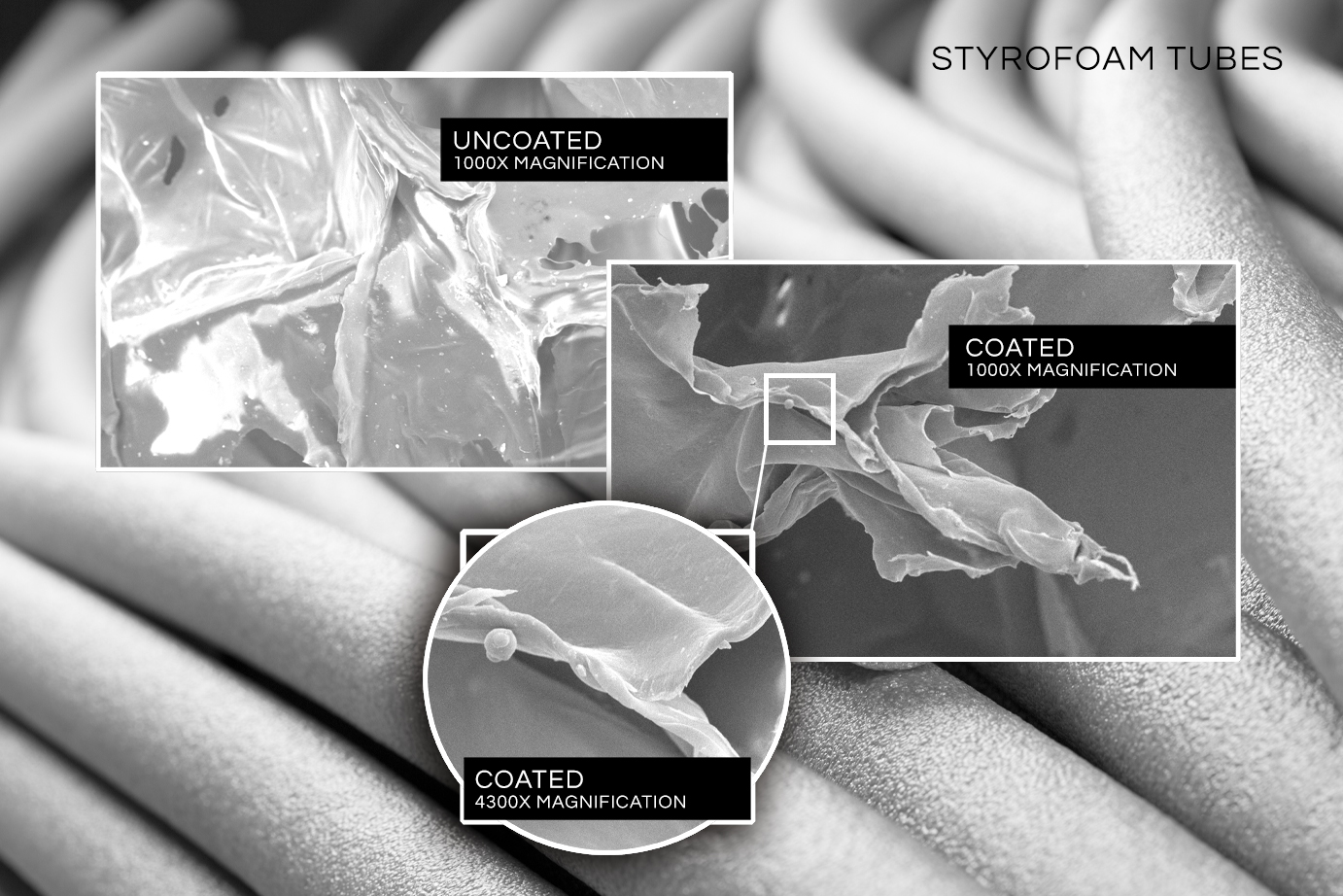

LUXOR’s unique A² technology generates a plasma and applies it in a controlled and accurate manner. This results in an extremely uniform, thin and homogeneous gold or platinum layer on your non-conductive material.

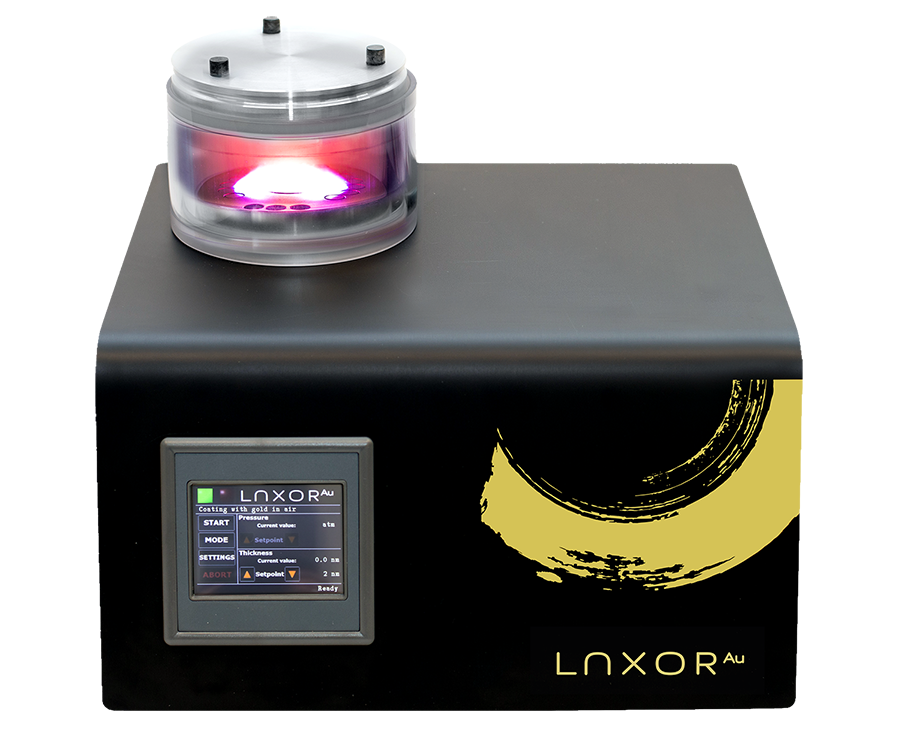

The LUXOR coaters are renowned for their speedy operation and ease of use. They ensure high-quality SEM images when working with challenging samples such as beam sensitive and non-conductive materials.

A2 Technology

LUXOR’s unique A² Technology generates a metal plasma and applies it in a controlled and accurate manner, resulting in an extremely uniform, thin and homogeneous gold layer. This is achieved by creating a vacuum in the process chamber, after which a high voltage is applied. Next, the coating current is automatically regulated by adding small amounts of process gas into the reactor, until the set target current is reached and stabilised.

The unique way this process is controlled and adjusted is what distinguishes the LUXOR metal coaters from other commercially available instruments. For the SEM operator this means more homogeneous metal coatings, resulting in high resolution and high contrast images and a worry-free coating process without any manual intervention.

Upside down design

In LUXOR metal coaters, the samples are mounted upside down. While this might seem a little controversial at first sight, it is actually a consequence of our ‘form follows function’ approach.

The upside down concept brings many advantages. First, all high voltage and high current wires are safely hidden within the sputter device. This obviously greatly reduces the risk of electric shocks.

Next, the sample loading station is easily accessible and allows to apply or remove the samples without the need for special tongs or tweezers. This doesn’t just make everyday use easier, but also speeds up productivity.

The upside design makes sure that loose particles will be removed during the coating process. This way, your SEM is optimally protected.

Fully automated

The coating process is fully automated. As soon as your samples are loaded into the preparation station, you only have to choose the desired coating thickness and push the start button.

Thanks to this user friendly process, the chance of human errors is significantly reduced. Furthermore, this means that untrained operators and lab personnel can operate the device.

BENEFITS OF METAL COATING

– Reduced microscope beam damage

– Increased thermal conduction

– Reduced sample charging (increased conduction)

– Improved backscatter and secondary electron emission (signal to noise ratio)

– Reduces the beam penetration and optimizes the spatial resolution of the backscattered signal, with improved edge resolution as a result

– Protects beam sensitive specimens