![]()

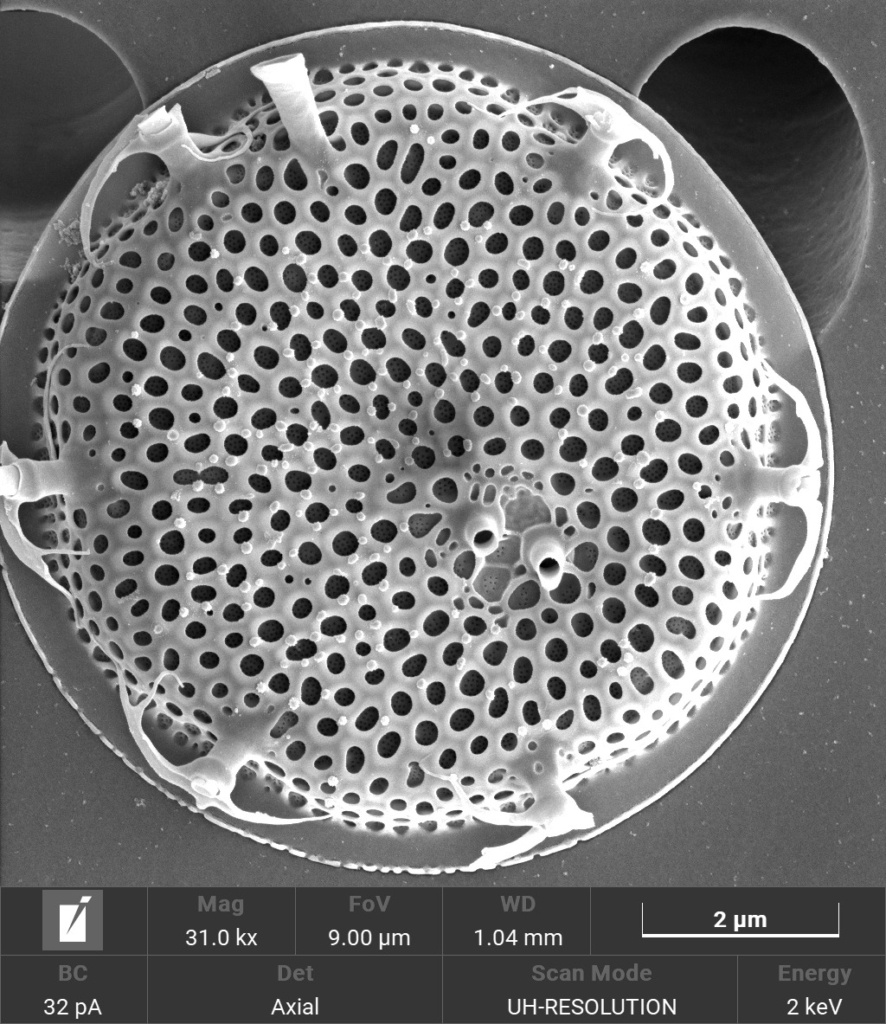

Succesfull industrial and academic SEM labs where image quality and high-resolution imaging are of paramount importance consistently choose LUXOR sputter coaters.

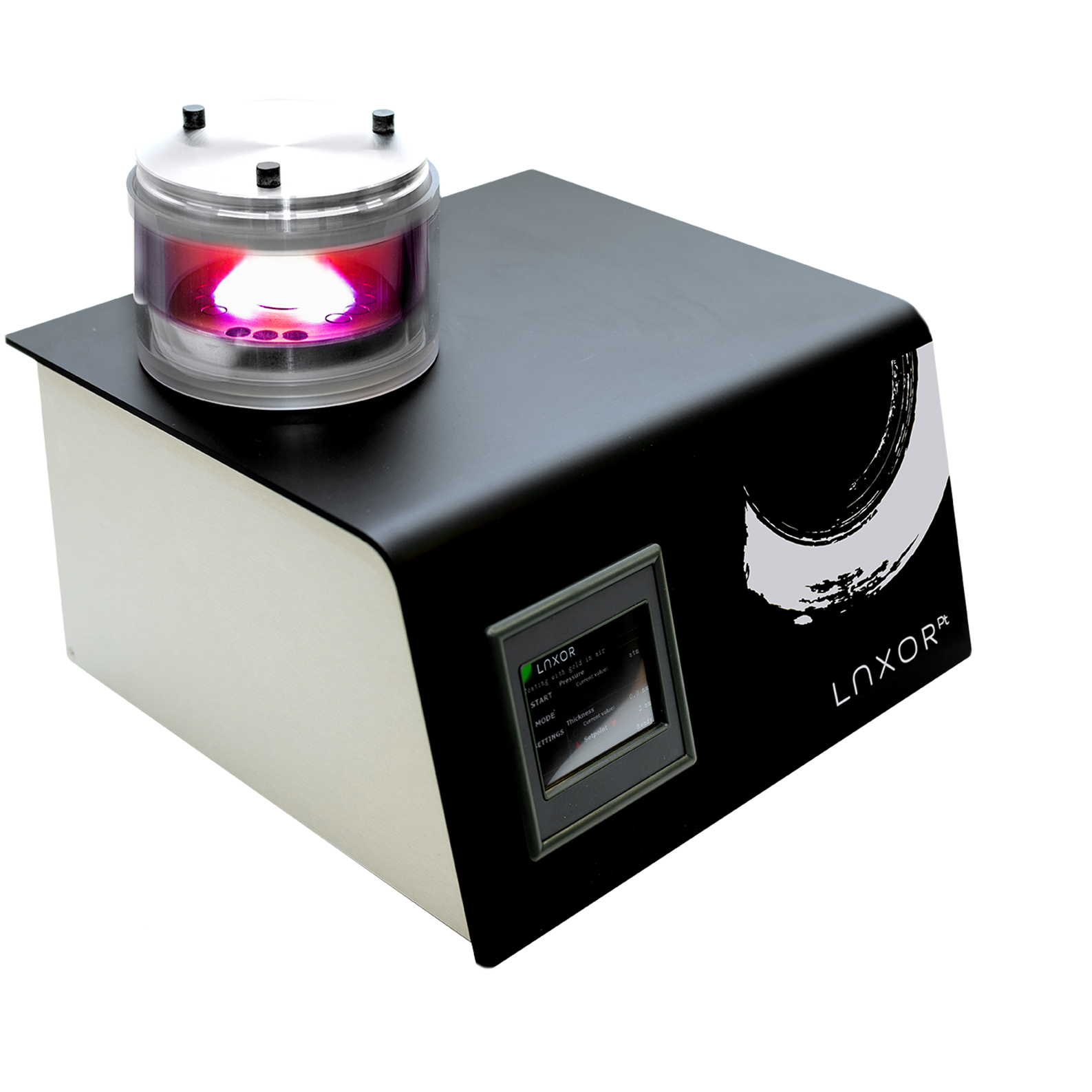

The LUXORPt sputter coater is an advanced, fully automatic sputtering device for use with high resolution floormodel SEM or FEG-SEM for magnifications from 50.000x upwards.

The platinum target is easily interchangeable when coating with gold or gold/palladium is preferred. The LUXORPt is also renowned for its ease of use and quick, hassle-free operation.

Technology

The LUXORPt is typically used for SEM imaging applications from 50.000x magnification upwards, where sample charging might be an issue. It applies the unique A² technology to coat your samples with a homogeneous platinum layer.

The LUXORPt sputter coater comes with all accessories and auxiliary parts, Combined with the optional vacuum pump it forms a fully functional sputter coating unit. Sample holders for standard pin stubs, cylindrical stubs and resin embedded samples are also available.

This model can also be fitted with a gold or gold/palladium target

If you are looking for a standard SEM resolution sputter coater for imaging applications below 50,000x then check out the LUXORAu sputter coater.

Want to learn more about coating technology? Download here our 4 part E-book on sputter technology for electron microscopy.

Benefits

SUPERIOR COATING RESOLUTION

Research and field tests show that the LUXOR Pt generates exceptionally homogeneous platinum and gold coatings, while only using a robust primary dual stage pump. Moreover, the incorporated LUXOR A² technology ensures consistent and identical coating, day after day and year after year.

FULL AUTOMATION AND EASE OF USE

FULL AUTOMATION AND EASE OF USE

The LUXOR Pt is remarkably easy to use. The required coating thickness is selected with the built-in touchscreen, and the coating process can be initiated simply by pushing the START button. No need for manual intervention to control the pump, voltage, vacuum, current or timer. It’s all fully automatic and constantly monitored by the coater.

INCREASED SPEED & EFFICIENCY

INCREASED SPEED & EFFICIENCY

The LUXORPt is able to process up to 7 samples in one go. And while the sputter coating procedure is very precise, it is also remarkably fast.

ADVANCED OPERATOR AND SEM PROTECTION

ADVANCED OPERATOR AND SEM PROTECTION

The unique ‘upside down’ design of the LUXOR Au means more protection for the operator and for your expensive SEM column.

ROBUST DESIGN, MADE IN GERMANY

ROBUST DESIGN, MADE IN GERMANY

Despite its small footprint and sleek appearance, the LUXORPt is a robust, sturdy device. It is designed and manufactured to be used intensively and run hassle-free for many years.

Features and specifications

- Coating with platinum, gold or gold/palladium in air or argon

- Maximum capacity: 7 x Ø 12.5 mm or 3 x Ø 25 mm stubs

- Average coating time:

- 5 minutes based on a 10 nm gold or gold/palladium coating

- 5 minutes based on a 5 nm platinum coating

- Additional high vacuum mode for outgassing

- Additional low vacuum (150 Pa) mode for drying sensitive samples

- Process time: 1 to 600 minutes (continuously selectable)

- Low energy dual stage pump (to be ordered separately)

- Au/Pt layer thickness: 1 to 100 nm (continuously selectable)

- Coating thickness: 1 to 100 nm (continuously selectable)

- Advised coating thickness for platinum is between 1 and 5nm

- Advised coating thickness for gold or gold/palladium is between 5 and 15nm

- Process chamber: Borosilicate glass Ø 100 mm x 150 mm height

- Plasma reactor: Borosilicate glass Ø 100 mm x 150 mm height

- Vacuum connector: DN 16 KF

- Gas supply: Environmental air (1 bar) or argon (0,6 bar)

- Dimensions: 340mm x 340mm x 290mm (W x D x H)

- Weight: 12 kg

Vacuum pump

- Can be ordered separately as “pump kit” including

- Two-stage roughing-pump with a pump capacity of 4.8 m³/h

- Metal vacuum hose, DN 16 KF, length 1 m

- 2 x fittings and 2 x seals DN 16 KF

- 1 x oil mist filter